Production center

We firmly believe: advanced equipment and technology is a solid foundation for the production of high-quality products, and consolidate every detail and step is a development belief we always adhere to. The professional standard, advanced technology, complete supporting facilities and perfect quality assurance of the excellent production center have helped UTA form a complete production system of stamping, surface processing and spare parts assembly since its establishment more than 20 years ago.

Stamping plant

Having introduced the punch from SEYI, a large equipment factory in Taiwan Island, and combined with continuous die stamping, UTA hinge stamping plant integrates all the processes needed for stamping accessories on the same die, realizing the two advantages of precision stamping and improvement of production efficiency. In addition, we further improve the continuous die technology to achieve the European stamping level. In the hinge industry, stamping technology continues to lead the industry.

★ Comparison: in general, small manufacturers still use single punch die for stamping production, which consumes manpower and time, and the great product size error often results in the instability of the product quality.

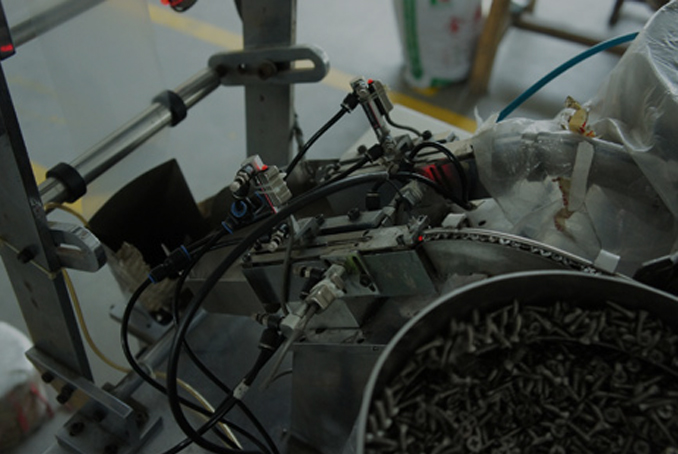

accessory center

UTA uses wire rod imported from Japan to produce small parts such as screws and springs. Even for small parts, UTA insists on independent production, and adopts imported automatic production equipment to control its size stability. High quality screws enable the hinge to fully play the function of compactness and adjustment, and the spring also affects the effect and life of the opening-and-closing hinge door.

Whether it's materials, equipment and production process, small parts are still treated with high standards.

★ Comparison: Small factories do not pay attention to small parts, and poor precision will indirectly affect hinge function.

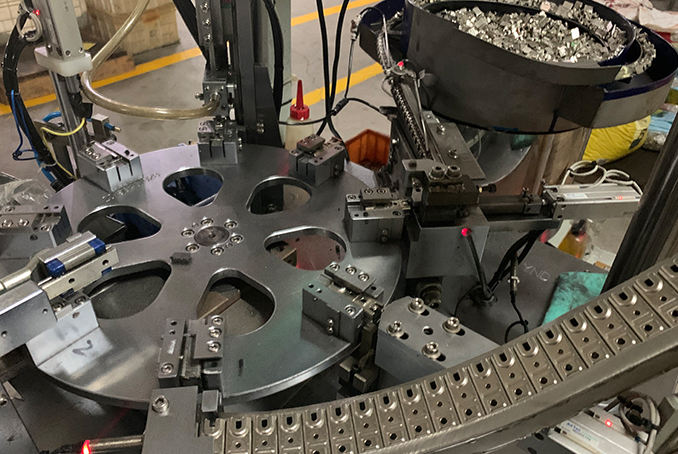

Assembly plant

The assembly of hinge strongly affects its function and service life. Therefore, semi-automatic production is adopted in the production line so as to reduce the defective rate caused by human operation and improve the stability of the product. All the assembly tools are designed according to the unique structure of UTA hinge, with an aim of achieving the stable assembly quality and improving the production efficiency at the same time.

★ Contrast: The small-factory assembly mode, featured in low tightness, is easier to produce abnormal sound and affect hinge life.